Consulting

Environment

Decarbonized shipping requires new solutions – are 2G biofuels the answer?

Photo: Pixabay

Biofuels are making waves in the marine industry – from ship-owners to engine makers, there is rising interest to get away from CO2-heavy traditional fuels.

Biofuels are a category of gaseous or liquid fuels generated from biomass – materials of biological origin. They can be created from various sources, or feedstocks, using a variety of processes. Presently, we are seeing the rise of the second generation biofuels which are made of non-food biomass.

Photo: Bureau Veritas

On the surface, it does seem like biofuels would be – technically speaking – an easy decarbonization solution for shipping. Biofuels are, after all, suitable for all vessel types: large, small, deep-sea or short-sea, gas- or liquid-fueled, without major adjustments. Biofuels or blended biofuels would both be lower carbon alternatives to fossil fuels from a well-to-wake perspective.

Also, as biofuels can be produced around the world, and present no significant complications for bunkering, initial infrastructure would not pose a major challenge or require a great deal of money.

Start with sustainable

Julien Boulland, Global Market Leader for sustainable shipping at Bureau Veritas, says that biofuels must be sustainable, suitable and available in order to make a notable splash in the maritime.

Photo: Bureau Veritas

“Second generation biofuels can be blended with regular fuel, with sometimes a 10-20% share – or, in some cases, as high as 50%,” he says, pointing out to the fact that the sustainability factor clearly is there. With a proper sustainable production pathway in place, biofuels promise significant carbon emissions reductions in comparison to standard fossil fuels.

Suitability seems like a no-brainer, too: One of the major advantages of biofuels is the maturity of compatible engines. Vessels typically require no modification to use biofuels, making them – basically – a convenient “drop in” replacement for conventional marine fuels. This gives biofuels a leg up on most other alternative fuels – such as hydrogen, ammonia and LNG – since they all require specific engines or fuel storage and supply systems.

Full steam ahead!

Patrick Jan, Expertise Leader for Environment Innovative Engines and Alternative Fuels at Bureau Veritas, confirms that modern engines are designed and developed for continuous operation on biofuel, without retrofit and without reduction in the rated output.

Photo: Bureau Veritas

“Regarding the fuel system on board, no major modification is to be considered,” he says.

However, a detailed biofuel specification needs to be documented to validate this approach. “This includes, for example, the allowed maximum injection viscosity, because if this value can’t be achieved with an unheated fuel, the fuel system has to be equipped with a heater,” Jan says.

Since ships today are equipped with heating capabilities to inject fuels with viscosity as high as 700 cSt into the engines at the recommended viscosity (10-18 cSt, depending on type or make), means this might not be an issue at all.

Volume business

But then there is the question of availability. At current production rates, biofuels are unlikely to be able to meet a large proportion of global maritime demand. In addition, competition with other sectors (such as land-based transportation and aviation) may add to availability woes.

“Availability is the big challenge, but there is lots of R&D under way to solve this issue,” Boulland says. Still, there are estimates that biofuels could eventually power 30% of the global fleet.

Andreas Ullrich, Global Market Leader, Passenger Ships & Ferries, at Bureau Veritas adds that government incentives can provide some needed boost to improve the situation, but the required biomass volumes are, indeed, challenging.

Photo: Bureau Veritas

“Not every waste is suitable to make biofuels. In addition, there are costs involved, too: you can never forget about the price tag,” Ullrich says, adding that cost structures also guide development efforts.

Global standard lacking

Taking a closer look at biofuel production pathways, there are more challenges there, starting with securing sustainably produced biomass. As it stands, there is currently no global standard to verify end-to-end green production pathways for biofuels.

Also, you need to allocate limited resources ethically, meaning that the land used for the production of biomass (or the biomass itself) may be needed to meet some other societal needs.

However, the regulatory situation for biofuels is gradually improving. The International Maritime Organization (IMO) is presently developing guidelines for the life cycle GHG analysis of marine fuels, which is expected to be the cornerstone when considering the emissions reduction potential of marine biofuels.

And while specific biofuel regulations may still be in the early stages, ship operators are already adapting their fleets to comply with IMO emissions regulations – and biofuels may be part of the solution to reducing emissions and meeting compliance requirements.

Biofuels also appear to be in line with NOx emission limits. The challenge, however, comes in proving compliance. This may require onboard emission testing or engine and fuel-specific NOx emissions validation testing. However, the IMO regulations now consider blends of 30% biofuel or less in the same way as traditional oil-based bunkers.

Time to get ready

To help the industry prepare for the use of biofuels/biofuel blends, Bureau Veritas created its BIOFUEL READY notation. It provides a set of requirements and comprehensive guidelines for the necessary documentation and testing.

“When granting the additional class notation BIOFUEL READY, a ship memorandum is endorsed in order to record the specification of the biofuels intended to be used, the blend ratios and the types of blends, as well as the list of engines covered and their main destination, either auxiliary or propulsion,” explains Patrick Jan.

Jan feels that from regulations point of view, it is crucial to have a certified biofuel, fuel quality for the engines and CO2 equivalent for the impact on the environment, available on the market. “From operational point of view, it is the same engine operation and installation as for the distillate fuels, with fuel specification based on the ISO 8217:2017(E) standard.”

Photo: Pixabay

Do your homework

The Bureau Veritas trio points out that it is always recommended that operators interested in operating on biofuels perform a due diligence about the ship installation, train the crew and ensure that the biofuel used either meets the requirements of ISO 8217 as well as EN 14214 (FAME) or EN 15940 (HVO).

“For non-FAME or non-HVO based products, more detailed understanding about the properties and characteristics should be sought prior to deciding if that specific biofuels should be trialled,” adds Patrick Jan.

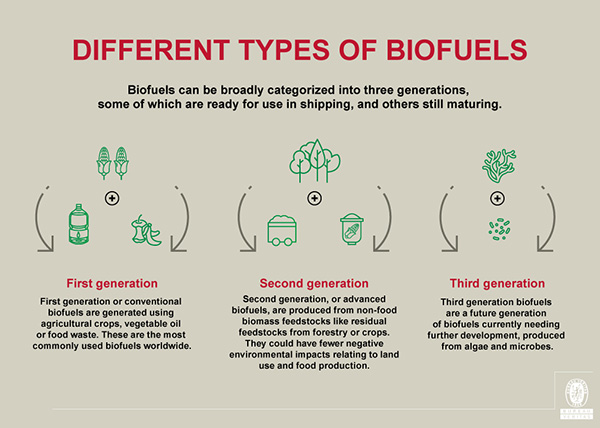

Three Generations of Biofuels

- First generation (also known as conventional biofuels) are produced from agricultural crops, vegetable oil or food waste. Fatty-acid methyl ester (FAME) and hydrotreated vegetable oil (HVO) are the main types used in the shipping industry.

- Second generation (AKA advanced biofuels) are made of non-food biomass feedstocks like lignocellulosic biomass – residual feedstocks from forestry or crops. Their environmental impact is expected to be lower than the first generation.

- Third generation, a future generation produced from algae and microbes, will need further development before it is fit for wider uptake.

Well-to-wake emissions

Well-to-wake refers to the entire process from fuel production and delivery to use onboard ships, and all emissions produced therein.

by: Sami J. Anteroinen