Environment

Systems

Use of methanol fuels will reduce ship emissions

photo: UNSPLASH

With the advent of constantly tightening IMO regulations on the environmental emissions in maritime traffic, new solutions for ship fuels are sorely needed. Shipyards are starting to turn to

methanol, a promising and viable ”green” fuel alternative.

To reduce ship emissions, new types of

non-fossil fuels are called for.

A system that supplies methanol fuel

to ship engines could be useful in stopping

environmental emissions of, say, SOx and

NOx emissions, as well as harmful particulates.

”Pilot projects for the use of methanol

in marine engines started around

2015. However, large-scale utilisation of

methanol did not commence until 2022,”

says Mr. John Bergman , CEO of Auramarine

based near Turku in Finland. The company

has a long history of various marine

fuel supply solutions.

”These days, shipyards in China

and South Korea are largely resorting to

methanol-fuel engines in their shipbuilding.

Methanol fuels are a growing market,

with many shipowners considering methanol

conversions for their existing fleets.”

Within Auramarine, the development

of methanol supply units and other methanol-

fuel solutions was started in 2020.

The task was given to a team of fifteen

R&D engineers.

”One of our first clients in this field

is the Swedish shipowner Terntank who

is currently having three new ships under

construction at a Chinese shipyard. Auramarine

will deliver methanol-fuel equipment

for them – including automation and

accessories – by June 2024. Other projects

are ongoing or being finalised,” Mr. Bergman

mentions.

FINDING THE RIGHT VARIABLES

In an era of constantly tightened international

regulations on ship emissions,

increasing the use of methanol fuel in ship

engines is an obvious choice.

According to Mr. Bergman, the specifications

of methanol-fuel systems are typically

determined on a case-by-case basis

according to ship and engine types.

In Auramarine’s solution, the methanol

supply unit will provide methanol from

the service tank to the master fuel valve

while regulating the flow, pressure and

temperature of the methanol. When combined

with filtration, this ensures its suitability

for use in engines. The system actively

maintains the supply pressure within the

specified tolerances in the course of any

load changes.

“To cut greenhouse gas emissions,

methanol is one of the most viable clean

fuels,” notes Bergman.

John Bergman, CEO, Auramarine Ltd.

photo: AURAMARINE LTD

”There are many variables in the

design of optimal systems. Also, the overall

reduction of the ship’s emissions is based on

several factors. Even the quality of the methanol

fuel being utilisted can be relevant.”

”In accordance with IMO regulations,

ships running on alternative fuels

need to have a back-up fuel system for

MGO marine diesel oil. Even with ships

utilising methanol as the main fuel type,

some 5 to 10 percent of MGO is generally

needed as ignition fuel. With a combination

of green methanol and bio oil as

ignition fuel, emissions can be significantly

reduced,” Bergman points out.

”When existing ships are converted

for methanol fuel, possibly new fuel

tanks are required. The necessary space

for them just has to be found somewhere

on board.”

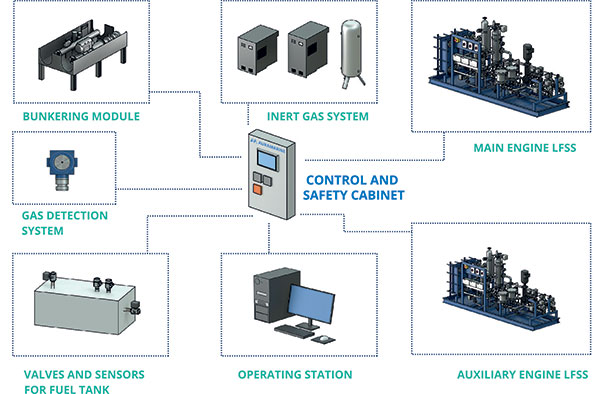

Auramarine Methanol Supply Unit.

photo: AURAMARINE LTD

LARGE MARKETS IN ASIA

Typically, Auramarine will deliver the methanol

supply system hardware – apart from

the fuel tanks – as well as the fueling system

with methanol supply pipes, junctions,

balancing pumps, sensors, valve units, and

automation, including software.

”Quite a lot of automation is

required. Methanol is a fuel with a low temperature flash-point so the automation

systems need to be approved by the

marine shipping classification company.

This type of automation is Auramarine’s

core expertise and know-how,” Bergman

adds.

”Our R&D engineering department

has invested heavily in this field as we see it

is essential for the future of marine traffic.”

The equipment is manufactured

either at Auramarine’s own factory in

Shanghai, China, or by trusted manufacturing

partners in Finland.

”Asia is our main market area. Our

Shanghai factory has been in operation

for 22 years already. Currently, China and

South Korea are the leading shipbuilders

worldwide in terms of volume.”

”The system will be delivered ready

for assembly to our customers who in turn

will install the system on board. Auramarine

will then handle the testing at sea,”

explains Bergman.

TAILORED SYSTEMS

AND FINE-TUNING

According to Mr. Bergman, the particularly

challenging part in the development work is that the technology is quite innovative

and therefore new for everybody involved.

”Acquiring knowledge of the whole

system is a full-time learning process. Optimising

the ship emission reductions has to

be worked on a ship-by-ship and engineby-

engine basis. There’s a whole lot of variables

to be considered.”

Furthermore, the type of methanol

fuel being utilised in ship engines can be

significant.

”Some types of methanol are being

manufactured by using fossil fuels while

other types may be synthetically produced

from environmentally friendly raw

materials. Such differences have an effect

on the total environmental impact of

methanol.”

Auramarine Methanol Supply System – Full fuel system from design to commissioning and lifecycle services.

photo: AURAMARINE LTD

SAFE SOLUTIONS FOR

HAZARDOUS AREAS

The Auramarine supply unit is designed

to fit on closed and Ex rated hazardous

areas where fire-safety is of paramount

importance. The health and safety guidelines

have been taken into account.

This level of safety is achieved by

using self-draining mechanical design in conjunction with the nitrogen inerting process

and specially designed configurations

to any serviceable methanol line segments.

Also, all components and electric equipment

will be selected for demanding use

in a hazardous area.

In order to minimize the volumes of

electrical equipment in a hazardous area,

the electrical cabinets and control panels

are designed to be fitted separately to a

safe area.

Auramarine’s methanol supply system

is suitable for all types of ships, regardless

of ship size.

”The key requirement is that the ship

will need an engine that is compatible with

methanol fuel. Quite often, some kind of

methanol conversion for the ship engine

will be required,” Bergman explains.

In his view, the demand for methanol

supply systems will skyrocket in the

near future.

”Green technology is becoming

increasingly important for the maritime

industries. A large portion of the world

trade is currently being transported by

sea. For such goals, clean fuel technology

would be just the thing.”

by: Ari Mononen