Environment

Systems

Auramarine ammonia fuel system

Modular, installation-friendly fuel supply system for engines and other ammonia consumers

Auramarine has 50 years of experience in delivering fuel supply systems for a variety of different fuels. These fuels include marine fuel oils (distillates and heavy residuals), natural gas, biofuels

and methanol. The latest addition to this product offering is our ammonia fuel systems. Why ammonia? If produced in a sustainable way, ammonia can be a zerocarbon fuel and, together with methanol,

a key part of shipping’s energy transition to net zero. This is also what makes it a valuable addition to Auramarine’s green portfolio.

Our primary focus is to deliver a safe,

reliable and high quality fuel supply system. We are, therefore, taking part in ongoing

ammonia research and development projects.

Furthermore, we actively co-operate with

different ammonia experts, ensuring that

we stay at the forefront of industry innovation.

The scope of our delivery is tailored

to our customers’ specific needs

but, as with our methanol systems, we

can provide holistic solutions that cover a

comprehensive

scope of delivery. Auramarine’s

ammonia fuel supply system is suitable

for both two-stroke and fourstroke

engines as well as other consumers. All

safety, design and material requirements

are strictly followed. Dedicated designs are available for both high-and low-pressure

arrangements.

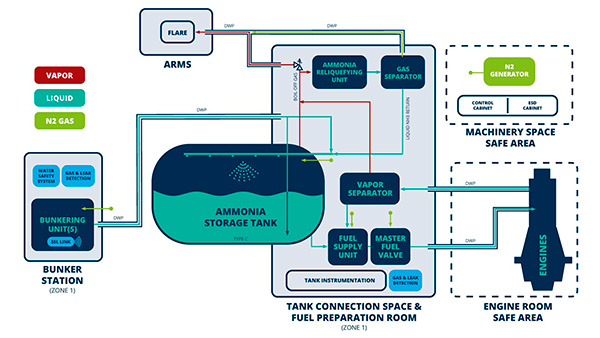

Example of a liquid ammonia system arrangement.

System scope

Auramarine’s most comprehensive scope

includes all necessary equipment from

bunkering through to fuel delivery for

onboard fuel consumers. More specifically:

bunkering units, fuel supply units, master

fuel valve manifold, reliquefying system,

ammonia mitigation system (ARMS), gas

and leak detection, bunkering water safety

system, ammonia control and safety system,

nitrogen generation system, as well

as tank design. Features of some main

components are presented next.

Functions and safety features

Bunkering station

- Leak detection, water safety system and a ship-to-shore link.

Auramarine tank design

- Design for tank connection space (TCS) to C-type tanks.

- Integration allows for compact installation.

Ammonia fuel supply unit

- Actively regulates and maintains the correct fuel pressure

and temperature.

- Measures fuel consumption.

- Filters impurities from liquid ammonia that could damage

the consumer.

Master fuel valve manifold

- Allows for isolating and nitrogen purging of one or

several consumer(s) from the system by utilizing double

block-and-bleed arrangements.

Nitrogen generator

- For purging & inerting of the ammonia system.

Vapour & gas separators

- Separates ammonia vapour from liquid ammonia,

where needed.

- Extraction of nitrogen and other trace gases from the

ammonia system.

Ammonia reliquefying unit

- Reliquefies boil-off gases from the ammonia storage tank

and other vapour sources.

Ammonia release mitigation system (ARMS)

- Featuring controlled combustion, capable of handling

ammonia release from the system.

- Ammonia content measurement.

Ammonia gas detection system

- Detects possible gaseous leaks.

- Alarm levels for personnel protection and explosive

atmosphere prevention.

Automation system

- Control of fuel supply unit and master fuel valve manifold

functions.

- Automatic purging of block-and-bleed valves.

Pilot fuel supply & diesel backup system

- Auramarine can offer pilot fuel supply system and fuel supply

system for the ships first fuel (e.g. bio-diesel).

More Information: www.auramarine.com